In the highly competitive personal care market, shampoo factories play a critical role. These specialized manufacturing facilities are not just production sites—they are hubs for technological innovation, quality control, and market responsiveness. This article explores the operations of a modern shampoo factory, revealing how raw materials are transformed into effective hair care products and why choosing the right factory is essential for brand success.

Why Shampoo Factories Are Key to Brand Success

A shampoo factory is more than a production unit—it is the core link between R&D, manufacturing, and the market. In today’s market, where ingredient transparency and proven efficacy are highly valued, the factory’s expertise directly determines product quality and market performance.

Three Core Strengths of a Modern Shampoo Factory

Research & Development and Formula Innovation are primary strengths of leading shampoo factories. Equipped with advanced labs and skilled chemists, these factories develop targeted formulations based on market needs—whether for scalp sensitivity, color protection, or damage repair. Their R&D capabilities shape a product’s unique selling points. Beyond basic formulation, they conduct in vitro tests and clinical trials to verify effectiveness and safety.

Strict Quality Control Systems ensure consistency and safety. Reputable factories implement full-process quality management—from auditing raw material suppliers to testing every batch, monitoring production in real time, and inspecting finished products. Stability, microbiological, and performance tests are standard. This rigorous approach builds long-term trust with brands and consumers.

Compliance and Sustainability Focus is increasingly important. Professional factories stay updated with regulations such as FDA, EU Cosmetic, and China’s Cosmetic Supervision laws, ensuring smooth market entry. Many also offer eco-friendly options like sustainable packaging and reduced carbon footprint solutions, supporting brands’ green initiatives.

Inside a Shampoo Factory: From Concept to Finished Product

Understanding a factory’s workflow helps brands choose the right partner. Modern shampoo manufacturing is a precise blend of science and technology.

Phase 1: Research and Development

Market Analysis and Concept Design begin with understanding consumer needs—oil control, repair, hydration, etc. The R&D team then creates initial formulas, considering ingredient synergy, fragrance, texture, and user experience.

Formula Testing and Validation involve rigorous checks. Chemists use tools like rheometers to assess texture, perform stability tests under various conditions, and verify claims through clinical studies when needed.

Phase 2: Production Process

Raw Material Processing requires precise weighing and mixing. Ingredients like surfactants, conditioners, and actives are combined in controlled conditions to preserve efficacy.

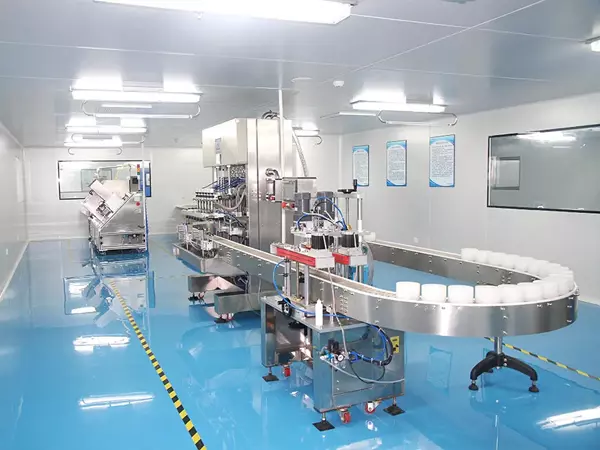

Emulsification and Packaging create the final product. Water-based and oil-based components are emulsified into a stable formula, then filled automatically into bottles. Packaging considers aesthetics, functionality, and durability. The entire process follows GMP standards in a clean environment.

How to Choose a Quality Shampoo Factory: Key Factors

With many factories claiming expertise, brands must evaluate potential partners carefully.

Technical and Operational Capacity

Advanced Equipment and Innovation matter. Look for modern mixing systems, automated filling lines, and modular setups that allow both small and large batches. Ask about special capabilities, such as developing water-free shampoos or probiotic-based formulas.

Certifications and Compliance are must-haves. Reliable factories hold certifications like ISO 22716 (GMP for cosmetics) and ISO 9001. Review their audit history, recall records, and ability to adapt to regulatory changes.

Service and Collaboration

Customization and Supply Chain Reliability set great factories apart. They should offer end-to-end support—from design and regulatory advice to logistics. Check their minimum order quantities (MOQs) and backup plans for supply chain disruptions.

Communication and Support ensure smooth partnerships. The best factories provide regular updates, quality reports, and technical assistance. They act as long-term allies, helping brands scale and improve.

A professional shampoo factory is a strategic asset for any hair care brand. It combines scientific expertise, stringent quality control, and operational flexibility to deliver products that meet market demands. In an era where consumers look for safe, effective, and sustainable options, partnering with a capable factory is a decisive step toward success.