The following list is based on a comprehensive evaluation of five core indicators: production scale, technology level, degree of intelligence, quality standards, and industry influence. The rankings are not in any particular order and cover flagship shampoo factories of international brands and leading domestic shampoo production bases.

I. Shampoo Factories of International Brands in China

1. P&G Tianjin Shampoo Factory

Located in Tianjin, it has an annual production capacity of over 300,000 tons, a water resource utilization rate of 95%, and an AI visual quality inspection system with an automation rate of 98%.

2. Unilever Hefei Shampoo Factory

Located in Hefei, Anhui Province, with an annual production capacity of 250,000 tons, it operates in a dark production mode, employs a pull-type intelligent feeding system, and is a carbon neutrality benchmark.

3. P&G Guangzhou Shampoo Factory

Located in Guangzhou, it is one of the largest daily chemical production bases in South China with an annual production capacity of over 200,000 tons. Its flexible production lines allow for rapid product switching, and it features a digital traceability system.

II. Leading Local Shampoo Factory in China

4. Jindao Intelligent Shampoo Factory

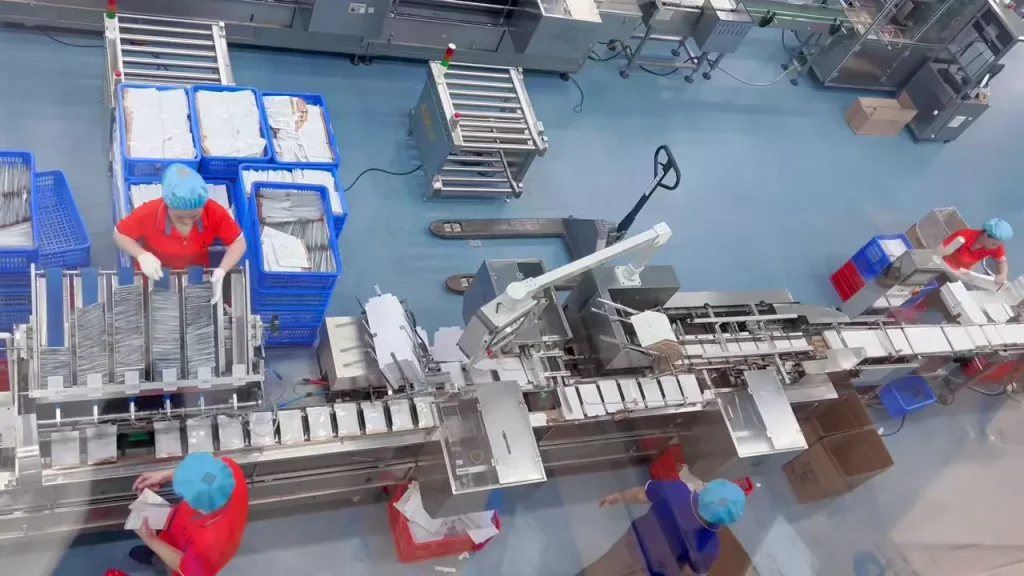

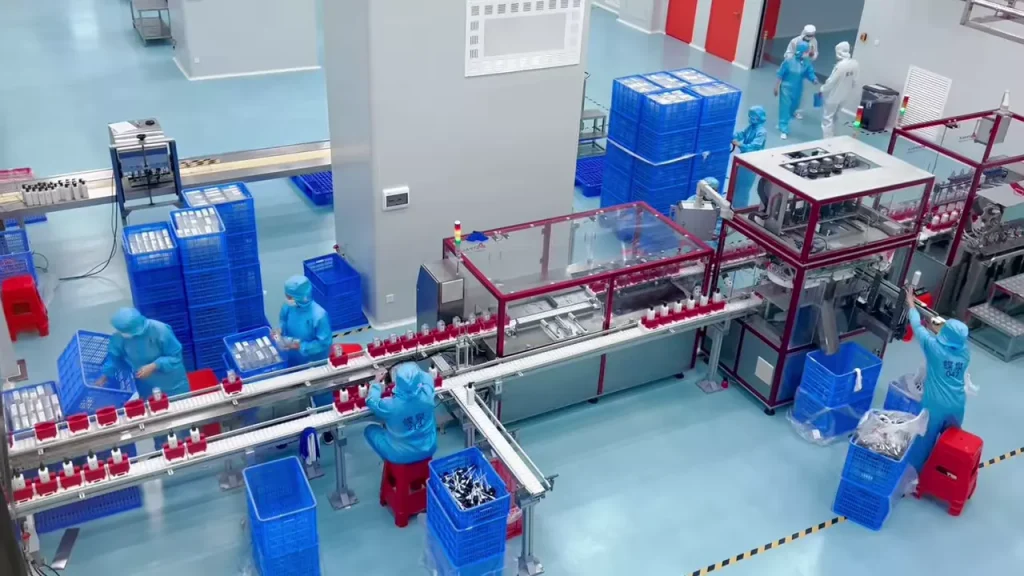

Located in Guangzhou, it is China’s first fully integrated intelligent manufacturing factory in the shampoo and conditioner industry, featuring 12 fully automated filling lines with an accuracy of ±0.5g and an annual output of 200,000 sachets.

Features and Advantages of Jindao Intelligent Shampoo Factory:

- Advanced Formulas: Jindao’s R&D team has developed unique shampoo formulas. These formulas are based on in-depth research into hair physiology and the latest hair care trends. For example, some of their shampoos contain natural plant extracts such as aloe vera and ginseng, which effectively nourish hair and scalp, making hair healthier and shinier.

- Quality Assurance: Jindao strictly controls the quality of its shampoos, from raw material procurement to the final product. A rigorous quality inspection system is in place at every stage of production. All raw materials are carefully selected and tested to ensure their safety and effectiveness. Finished products also undergo multiple rounds of testing to meet quality standards.

- Customization Services: Jindao offers customized shampoo services. Products can be developed according to the specific needs of clients, such as different fragrances, packaging designs, and functional features. This flexibility allows the company to meet the diverse needs of the market.

- Flexible manufacturing: enables small-batch, multi-batch production.

Website: https://theshampoofactory.com/

5. Lafang Shampoo Factory

Located in Shantou City, Guangdong Province, with a 100,000-level cleanroom, 6 emulsification lines + 12 filling lines, annual production capacity of 120,000 tons.

6. Beeflower Shampoo Factory

Located in Shanghai, with 7 fully automated production lines, infrared intelligent quality inspection, and full-process digital management, annual production capacity of 80,000 tons.

7. Bawang Shampoo Factory

Located in Baiyun District, Guangzhou City, a benchmark factory for traditional Chinese medicine anti-hair loss shampoo, GMP certified, with patented traditional Chinese medicine extraction technology and an intelligent traditional Chinese medicine fermentation system, annual production capacity of 60,000 tons, and the number one market share in the anti-hair loss category.

8. Huanya Shampoo Factory

Located in Huadu District, Guangzhou City, a pioneer in silicone-free shampoo, a national-level engineering technology center, and a microecological scalp care R&D base, annual production capacity of 120,000 tons, and the core production site for the Ziyuan brand.

9. Yunnan Baiyao Shampoo Factory

Located in Kunming City, Yunnan Province… Pharmaceutical background, pharmaceutical-grade production standards, scalp health testing center, sterile production environment

10. Adolf Shampoo Factory

Located in Baiyun District, Guangzhou City, a benchmark for fragrance-based shampoo and conditioner production, with an intelligent warehousing system, flexible production enabling small-batch, multi-batch production, annual production capacity of 100,000 tons+, and a digital management platform monitoring the entire production process in real time.

The aforementioned top ten shampoo factories in China each possess unique characteristics and advantages. These factories play a vital role in the Chinese and global shampoo markets. They not only meet diverse consumer needs but also drive the development of the hair care industry through continuous innovation and improvement. With the ever-growing demand for high-quality hair care products, these leading factories are expected to continue their growth and make even greater contributions to the industry in the future.

III. Shampoo Factory Selection Guide

Before searching for a shampoo factory, please clarify the following four points, as these are the foundation for accurate matching:

1. Define Your Positioning and Needs

- Product Positioning: High-end/Mass Market/Functional (e.g., anti-hair loss, dandruff removal, repair)/Natural & Organic/Specialty Shampoos & Conditioners (e.g., children’s, men’s, dyed hair products)

- R&D Capabilities: Do you have mature formulas, or do you require the factory to develop from scratch or provide a library of mature formulas to choose from?

- Production Capacity and Order Quantity: Initial order quantity and expected annual output. This directly determines whether the factory is willing to accept the order (factories have minimum order quantity (MOQ) requirements).

- Budget Scope: Product cost target (RMB/bottle), including the entire supply chain such as raw materials, packaging materials, production, and testing.

2. Shampoo Factory Type Selection

- R&D-Oriented Factories: Possessing strong R&D teams and laboratories, specializing in formula innovation and efficacy verification, suitable for new brands and functional products.

- Manufacturing-Oriented Factories: With strong large-scale production capabilities, high automation, and excellent cost control, suitable for established brands and large-scale, stable production of mass-market products.

- One-Stop Service Factories: Providing a full-chain service from market research, formula development, packaging design, production and filling to quality inspection and registration, suitable for brands seeking a hassle-free experience.

- Specialized Factories: Focusing on a specific area, such as all-natural organic products, silicone-free technology, or specific ethnic ingredients.

3. Verifying Core Qualifications and Capabilities

- Essential Basics: Valid Business License and Cosmetic Production License.

- Quality System: Whether the factory has passed international certifications such as ISO9001 and ISO22716 (Cosmetic GMPC), which are key indicators of production standardization.

- R&D Laboratory: Whether the factory has its own laboratory, the sophistication of its R&D equipment, and the qualifications of its R&D personnel.

- Production Capacity and Equipment: Visit the workshop to understand the automation level of the filling line, the cleanliness level of the workshop, and whether the production capacity can meet your needs with flexibility.

- Supply Chain Capabilities: Is the supply chain stable? Are the raw material sources reliable? Can you provide relevant safety and compliance certificates for the raw materials?

IV. How to identify potential risks and pitfalls

- Certification Risks: Is the shampoo factory operating without a license or exceeding its permitted scope? Verify the details of the Cosmetic Production License.

- Raw Material Risks: Ensure the shampoo factory does not use prohibited ingredients and strictly controls the concentration of restricted ingredients. Require compliance certificates for all raw materials.

- Vague Pricing: Beware of “package prices.” Request a detailed price list from the factory, including: raw material cost, inner material processing fees, packaging material cost/procurement fees, filling and processing fees, testing fees, and registration service fees.

- MOQ Trap: Minimum order quantity is a crucial factor. Inquire about the MOQ for individual items, the minimum order quantity for raw materials (e.g., 1 ton), and whether “group ordering” is supported to lower the barrier to entry.

- Sampling Fees: Clarify whether sampling is free or charged, and the charging standard. This is a litmus test for R&D capabilities.

- Delivery Delays: The contract should clearly stipulate the entire process from order placement to delivery, and specify compensation for delays. Consider the impact of packaging material procurement cycles on the total delivery time.

- Lack of Quality Control Processes: Understand the factory’s inspection standards and processes for raw materials, semi-finished products, and finished products. Does the factory have an independent QC department and testing equipment?

- After-Sales Service and Problem Response: Clearly define the handling procedures, responsibility allocation, and compensation plans for quality issues (such as batch instability, packaging defects, etc.).

- Intellectual Property Ownership: If you are outsourcing R&D, you must clearly stipulate the ownership of intellectual property rights such as formulas and patents in the contract to avoid future disputes.

V. Key Points for Efficient Cooperation

- On-site Inspection: Seeing is believing. It is essential to visit the intended shampoo factory in person to observe the workshop, laboratory, warehouse, and management details.

- Request Samples: Test the factory’s efficiency, attention to detail, and the quality of the finished product through sample testing.

- Review Past Cases: Review the brands the factory has served to understand its strengths and market reputation.

- Contract is King: Clearly document all technical details (formula, process parameters), quality standards, delivery terms, division of responsibilities, payment methods, confidentiality agreements, etc., in the formal contract.

Summary: Choosing a shampoo factory is a systematic process, essentially finding a long-term, stable, and reliable strategic partner. We recommend a process of “clarifying your needs → broadly selecting potential factories → key inspections (qualifications/on-site visits) → sample verification → business negotiations,” making prudent decisions to lay the most solid product foundation for your brand. We wish you success in finding your ideal partner!